To coincide with the Cash & Payments Sustainability Forum™ in mid-November, Reconnaissance (co-publisher of Currency News™) issued a whitepaper – ‘What Goes Round Comes Round’. It describes a range of options for central banks (for whom waste disposal is not a core expertise) to dispose of their unfit cotton banknotes with the best environmental outcomes at the end of their life.

At the Forum, Royal Dutch Kusters, Hunkeler and De La Rue all presented data about how central banks dispose of unfit banknotes irrespective of the substrate they are printed on. Reconnaissance has concentrated solely on unfit cotton banknotes because the majority of the world’s banknotes are cotton based.

At the Forum, Royal Dutch Kusters, Hunkeler and De La Rue all presented data about how central banks dispose of unfit banknotes irrespective of the substrate they are printed on. Reconnaissance has concentrated solely on unfit cotton banknotes because the majority of the world’s banknotes are cotton based.

Last year Kusters wrote about a hierarchy of waste disposal (above), and this is a useful way to think about options for disposal. While landfill is at the bottom, there are a series of steps upwards offering better environmental options right up to repurposing and ‘upcycling’ waste.

There may be a perception that there are limited options for cotton banknotes, let alone that repurposing is possible or being done. Both would be incorrect, and we have gathered evidence and examples of what else can be done.

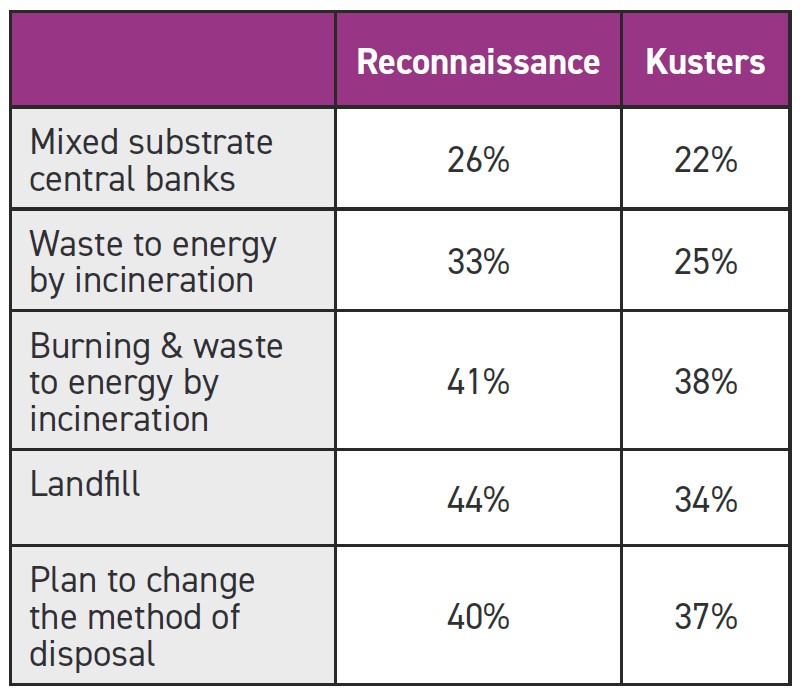

Reconnaissance received detailed feedback from 54 central banks who use cotton for their banknotes. Kusters shared results of its 82 central bank survey which included polymer-only central banks in addition. There is significant similarity in the findings.

For example, landfill remains the most widely used method of disposal, waste to energy by incineration is widespread, not just in Europe, uncontrolled burning remains widely used and the number of central banks with at least one polymer denomination is now quite common.

The desire to find new ways to dispose of unfit notes matches closely the landfill figure, but the data shows that many central banks are looking to move away from turning waste to energy by incineration and to move up the hierarchy.

The desire to find new ways to dispose of unfit notes matches closely the landfill figure, but the data shows that many central banks are looking to move away from turning waste to energy by incineration and to move up the hierarchy.

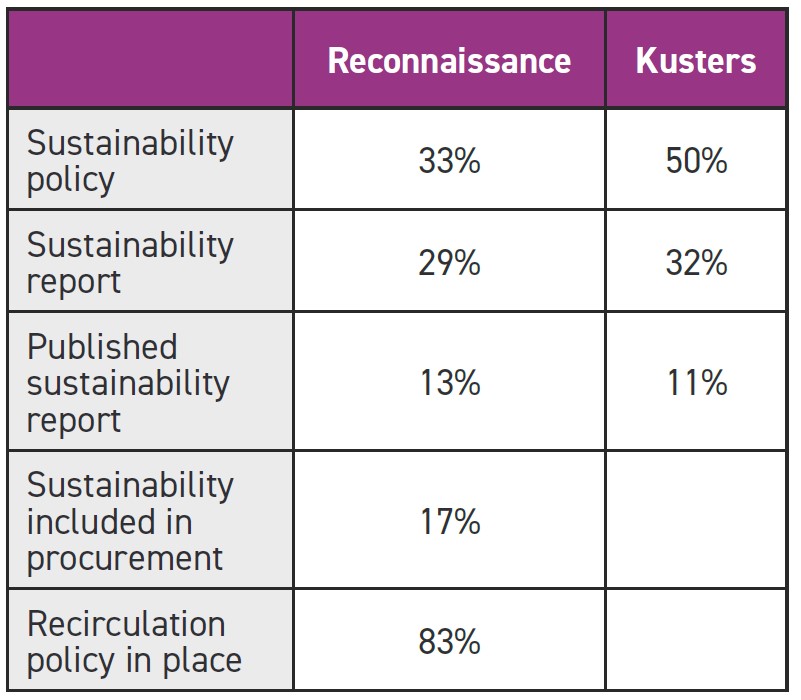

Sustainability is on the agenda of central banks, as can be seen below, but it isn’t yet, perhaps, mainstream. While many central banks commented that suppliers are selected based on being responsible and of good standing, including on sustainability, few actively award business based on sustainability criteria. The widespread existence of recirculation policies is an important tool in reducing cash movements and all of the environmental impacts that brings.

The Hunkeler/Banknote Industry News survey and the De La Rue customer data are harder to compare, but their data largely supports and reinforces the conclusions found here.

Kusters were told by 72% of central banks that they wanted to outsource the disposal of their banknotes to third parties. Even with that statement, the central bank team need to have a sound knowledge to organise that efficiently and to be confident that the waste is being disposed of as well as it can be.

The white paper suggests six activities that may be helpful:

1. Get an understanding of the different disposal options. The whitepaper contains a detailed overview of the science behind the options.

2. Research the national regulations on waste disposal for all the options. This will allow the central bank to be confident that its waste management company, or other third party, is responsible.

3. Get the banknote analysed to understand its properties if put in landfill, burnt or composted. Will the emissions and results of going those routes meet the national regulations?

4. Investigate what infrastructure exists for waste disposal locally. Are the landfill sites properly set up, maintained and managed? Do the incinerators have appropriate filters, burn hot enough and dispose of ash responsibly? Are there businesses that need heat for their processes, for example making cement, that could incinerate the notes? Are they composting or could it be set up? Are there innovative companies who are looking to make upgraded products (asphalt, bricks, insulation, high grade paper, furniture etc.)?

5. Model the cost/benefits of different options, considering distance and environmental impacts. This is particularly important if appropriate infrastructure is a long way from the shredding site.

6. Talk to information sources who have experience and expertise – national research institutes and universities, waste management companies, the equipment manufacturers of shredding machines, printers and paper suppliers etc. Attend conferences and webinars where this topic is on the agenda. All these organisations and sources will have useful experience and knowledge.

Landfill – landfill sites need to be managed so that leachates don’t pollute the water table. They should be clay lined and be organised to bleed off the methane that is generated. Unless they are actively managed, even when ‘closed’, they can damage the environment. Given the potential of cotton to be used for other things, putting it in landfill does not maximise its value.

Uncontrolled burning – combustion releases CO2 and toxins into the environment. It can also lead to contamination of the water table.

Waste to energy by incineration – to get best value from this approach, the incinerators need to burn at high temperatures and to be fitted with scrubbers that remove harmful particulates.

Cotton waste has a high calorific value and a low level of pollutants. It is, therefore, a good fuel source. In addition to being burnt to generate electricity, it can also be used in industrial processes that require heat, for example the production of cement. The furnaces need to burn at about 1,450°C. To reach these temperatures they usually burn coal or crude oil. Using cotton waste means these fossil fuels need not be burnt.

Gasification and pyrolysis have been investigated as techniques for burning banknote waste to allow it to be upcycled to create new products. The paper provides details of this research.

There are questions about the cost/benefit analysis of these methods, but the research has found that solid product can be produced to be used as fuel or as a raw material or additive material for several industrial activities, eg. medical, food, chemical industries, and for manufacturing products such as cables and house pipes. It can be used as dyestuff material in rubbers and to produce activated carbon, a support material for adsorbents and metal catalysts.

Composting – this is a well-established way to allow organic waste to be converted into material useful for growing crops and enhancing soil. Organic waste generally contains diverse materials generated by nature in their biochemical processes, such as cellulose, carbohydrates, proteins and vitamins, and obtained through biological synthesis processes such as the photosynthesis in vegetables.

The aerobic digestion process transforms these complex materials into elements assimilable by vegetables, making use of efficient micro-organisms that belong to the lactobacillus genera (acid lactic bacteria), Saccharomyces (yeasts) and Rhodopseudomonas (photosynthetic or phototrophic bacteria).

The white paper describes aerobic and anaerobic digestion. It details different approaches to composting and what must be done well for this to work well.

The whitepaper contains detailed information about work done by the Pakistan Security Printing Corporation in this area and by BioBanknote® in Colombia. There is reference to a Bank of England paper that has details of its carbon emissions of its soil enhancement programme before it adopted polymer as a substrate. Several central banks, including FedCash® Services in the US and the Central Bank of Colombia, compost their banknote waste as a matter of course.

The white paper goes into this detail because composting is an option which is relatively low tech and low cost, and which is feasible in most countries.

There are several examples where cotton material has been investigated or used to create new materials. In addition to having a high calorific value, cotton has other attributes which enhance products. For example, research in Turkey (which has a large cotton industry) found that adding the material to asphalt makes it less likely to crack in cold weather, since the cotton changes its tensile properties.

The Central Bank of Egypt has investigated removing ink from banknotes to allow the cotton to be used in creating high value cotton paper, such as stationery.

Landqart has worked with Hughes Energy to see whether steam autoclaving can be used to upcycle cotton banknotes and Durasafe®. The research continues but initial findings were positive. It appears that if the level of hydrolysis is controlled, it is possible that other products could be produced such as cellulose acetate, which is used in the textile and personal hygiene industry.

Finally, research shows that cotton waste can be used in making bricks and in reinforcing Portland cement concrete. FedCash® Services reports that 15% of US shredded waste is used in road surfaces and insulation. Oberthur Fiduciaire has also worked on creating acoustic tiles and cement blocks from the waste.

The ECB started gathering data on unfit banknote waste disposal in 2015 and decided to take steps to stop Eurosystem banknote waste being disposed of in landfill, and from 2023 onwards, National Central Banks (NCBs) are expected to avoid the use in landfill.

A number of countries have geographic challenges, the most obvious example being those many island communities. Shipping waste to appropriate disposal facilities can conceivably have a greater environmental impact than using local landfill. Recognising such a reality, the NCBs need to justify using landfill use and explain their plans.

Virtually all euro area NCBs are now using waste to energy by incineration.

The Central Bank of Colombia (CBC), meanwhile, issues about 1,100 tonnes of banknotes each year and needs to destroy about 500 tonnes of unfit banknotes. The CBC has six sites where banknotes are shredded. In Bogota, where over half of the total waste is created, it pays for the waste to be composted, including the cost of delivering it to the firm. The other sites used the shredded banknotes to make cement.

The CBC has worked with BioBankote® to develop the process and to ensure that the compost meets the rigorous regulatory requirements in Colombia. The compost produced by BioBanknote, called Biofort, meets Colombia’s high regulatory requirements to the extent that it can be used as compost to grow trees and for growing food. The CBC is using it to grow trees as part of its goal of being carbon neutral in 2023.

The composting plant that processes the CBC’s banknotes produces about 15,000 tonnes of compost a year from all sources. For countries that produce fewer notes there is an option to use a ‘Bioreacter’, a smaller unit and simpler self-contained unit processing batches of about 100kg of material.

Reports on the Kusters study, and some of the other examples and case studies named in this article (which were also presented at the Cash & Payments Sustainability Forum) will feature in subsequent issues of Currency News™.

The report can be downloaded at https://cashandpaymentsustainabilityforum.com/wp-content/uploads/2022/11/Re-purposing-banknotes.pdf.